Menu

Workplace Health and Safety

[[ sh ][ Introduction ]]

All workers have the right to a safe and healthy workplace. These rights are protected by law in all the states and territories of Australia. Historically, the laws that governed workplaces in Australia were very complicated with not too much consistency between the states.

The original laws governing workplace health and safety in most states were based on the English Factory Acts of 1844 to 1894. These Acts were introduced in England to try to improve working conditions in mines and factories that had been established during the Industrial Revolution.

The early Australian laws were mainly concerned with technical issues rather than trying to solve the health and safety problems that faced Australian workers. The current Acts and their Regulations are designed to protect the health and safety of all workers.

In this chapter we will talk about:

- understanding your Occupational Health & Safety obligations and following safe work practices

- identifying, reporting and controlling safety hazards on the construction site and assessing risks

- following emergency procedures.

[[ sh /n ][ WHS Legislation ]]

All Australian states and territories have occupational health and safety laws which are administered by the following government departments and authorities:

Queensland: Division Of Workplace Health And Safety; Department Of Employment, Vocational Education, Training And Industrial Relations. Workplace Health And Safety Act, 1995.

New South Wales: Workcover Authority Of New South Wales. Occupational Health And Safety Act, 2000. No. 40.

Victoria: Victorian Workcover Authority. Occupational Health And Safety Act, 1985.

South Australia: Workplace Services; Department of Administrative and Information Services. Occupational Health, Safety And Welfare Act, 1986.

Western Australia: Worksafe Division; Department of Consumer and Employment Protection. Occupational Safety And Health Act, 1984.

Tasmania: Workplace Standards Tasmania; Department of Infrastructure, Energy and Resources. Workplace Health and Safety Act 1995.

Northern Territory: Work Health Authority. Work Health Act, 1986.

Australian Capital Territory: Commissioner for Occupational Health and Safety. Occupational Health And Safety Act, 1989.

AIMS OF OH&S LEGISLATION

The current state occupational health and safety Acts aim to:

- ensure the health and safety of employees on the construction site

- protect visitors to the construction site, such as suppliers or subcontractors

- promote a work environment on the construction site that meets the physical and psychological needs of workers

- include codes of practice, standards, and joint consultation procedures to improve workplace health and safety

- regularly look over the current laws so they can be changed to suit changes in industry.

RESPONSIBILITIES OF EMPLOYERS

Your employer has first responsibility for your health, safety and welfare on the construction site. Current occupational health and safety legislation requires your employer to:

- make sure that all plant, equipment and work methods are safe and properly maintained at all times

- make sure that all substances found in the workplace can be used, handled, stored and transported safely

- make sure that you have safe access to and exit from the workplace

- provide all necessary training, information and supervision so that you know how to work safely and not endanger your health

- make sure that the health and safety of visitors to the construction site is protected

- provide and maintain a safe and healthy work environment

- provide information about safety precautions, any health and safety problems and research results that could relate to plant, equipment or substances used on the construction site.

RIGHTS OF EMPLOYERS

Employers have the right to expect all workers to comply with reasonable laws or rules which are meant to protect their health and safety in the workplace.

RESPONSIBILITIES OF EMPLOYEES

Occupational health and safety laws can only protect you if there is full cooperation between you and your employer. Your responsibilities under state occupational health and safety Acts are:

- to cooperate with your employer’s efforts to comply with all occupational health and safety responsibilities

- not to act in a way that endangers your own health and safety or the health and safety of others

- not to misuse or interfere with equipment or any other materials provided for health and safety purposes

- not to interfere with, hinder or prevent the giving of aid to someone who is injured, ill or endangered in the workplace.

RIGHTS OF EMPLOYEES

As an employee on the construction site you should have:

- a workplace that is safe and healthy where your physical and emotional needs are considered

- suitable training to help you do your job safely and without risk to your health

- constructive supervision to make sure that your work is being carried out in the proper manner

- information to help you understand the reasons for safe work practices that are introduced on the construction site.

REFLECT & RESPOND

Before leaving this page, think of what you’ve just been reading, and test yourself with these questions.

[[ mr /f ][ Which of the following statements reflect the aims of WHS legislation: – ][ Protecting the health and safety of employees. ][ * Ensuring that workers get their sick leave entitlements. ][ Protecting all people on construction sites. ][ Standards and codes of practice for improving health and safety. ][ * Providing employees with good diet and nutrition advice. ][ Sick leave and dietary advice aren’t part of WHS legislation. ]][[ mr /f ][ Employers are required under WHS legislation to ensure that: – ][ all equipment is safe to use and well maintained. ][ all substances are stored and used safely. ][ * all employees are paid award wages. ][ training and safety information is provided. ][ Wages and salaries aren’t a part of WHS. ]][[ mr /f ][ Employees are generally required to: – ][ act in a way that promotes health and safety on the site. ][ not interfere with equipment provided for WHS purposes. ][ * hinder the giving of aid to an injured person. ][ advise others about best practice related to WHS. ][ Giving aid to an injured person is a general expectation of any worker. ]]

[[ sh /n ][ On-Site WHS Information ]]

Information about health and safety matters on the construction site should be readily available to all workers. The principal contractor is required to make sure that all employees and sub-contractors are familiar with OH&S policies and procedures including workplace safety plans, work method statements and material safety data sheets.

The way occupational health and safety information is presented may vary a little between states. In addition, variations in the OH&S policies of large and small contractors may result in some differences in the information that is provided. At most construction sites you will find the following OH&S information.

CONSTRUCTION WORKPLACE PLAN / SITE SAFETY PLAN

The Construction Workplace Plan or Site Safety Plan is prepared by the principal contractor for the construction site. As well as contact details and a description of the type and duration of the work, the plan should set out the following:

- site safety rules (Refer to page 34 for an example of Site Rules.)

- risks to be managed

- risk control measures and their implementation

- arrangements for monitoring controls

- emergency procedures

- public safety strategies.

WORK METHOD STATEMENTS / JSA’S (JOB SAFETY ANALYSIS)

These statements are prepared for high risk construction activities such as working in deep trenches or confined spaces, using a hazardous substance or working at a height where a fall could cause serious injury. (Refer to page 35 for an example.)

They describe how you should perform the work in the safest manner as well as control and safety measures you must follow.

MATERIAL SAFETY DATA SHEETS

A material safety data sheet (MSDS) is a manufacturer’s document which contains important information about a hazardous substance. Refer to page 36 for an example. An MSDS must state:

- the product name of the hazardous substance

- the chemical name of ingredients

- chemical and physical properties of the substance

- health hazard information

- precautions for safe use and handling

- manufacturer’s or importer’s name and contact details.

An MSDS can be used to:

- identify the hazards associated with the substance

- check that the substance is being used in the manner intended

- decide whether improvements to control measures are necessary

- identify necessary control measures before the introduction of a new substance

- decide if workplace health monitoring will be necessary

- check the effectiveness of existing emergency procedures and equipment.

REFLECT & RESPOND

Before leaving this page, think of what you’ve just been reading, and test yourself with these questions.

[[ mr /f ][ Which of the following are typically included in a site safety plan? ][ Emergency procedures. ][ Site safety rules. ][ * Plans and specification. ][ Risk control protocols. ][ * Working conditions. ][ Plans and specs, and working conditions don’t relate to site safety. ]][[ mc /f][ Are Materials Safety Data Sheets (MSDS) prepared on site by the WHS Officer? ][ * Yes – they keep them in their office for your reference. ][ No – MSDS are supplied by the supplier of the materials. ][ They may be kept in the WHS office, but they are typically supplied by materials manufacturers. ]][[ mc /s /f ][ An MSDS contains: – ][ * The name of the substance. ][ * Precautions for safe use. ][ * Health hazard information. ][ All of the above. ][ MSDS contain all of this information. ]]

[[ sh /n ][ Safety Personnel ]]

WORKPLACE HEALTH AND SAFETY REPRESENTATIVE

On some construction sites a worker may be elected as the Workplace Health and Safety Representative. The main responsibility of this person is to consult with management on all matters which affect the health and safety of workers on site.

WORKPLACE HEALTH AND SAFETY COMMITTEE

A principal contractor or employer may establish a Workplace Health and Safety Committee for the construction site. The committee could assist and advise the principal contractor on carrying out OH&S policies and the site safety plan. Other duties could include looking at the way on-site accidents happened and telling workers about safety rules and procedures.

SAFETY OFFICER

The principal contractor may appoint a safety officer for the construction site. The safety officer would normally have undertaken some safety response training and would generally be the first person you would contact when an emergency or accident occurs on the construction site.

REPORTING EMERGENCIES

All workers have an obligation to report an emergency, accident, fire or safety risk as quickly as possible to the safety officer, site supervisor, manager or other senior person on the construction site.

REFLECT & RESPOND

Before leaving this page, think of what you’ve just been reading, and test yourself with this question.

[[ mc /f ][ What is the main responsibility of the WHS representative on site? ][ Consult with management on WHS matters that may impact the health of workers on the site. ][ * Maintain a record of all WHS incidents that occur on the site. ][ * Attend all site meetings to hear about WHS concerns from workers on site. ][ * Maintain all WHS paperwork in good order for audit purposes. ][ WHS representatives, first and foremost, look after the health and safety of workers on site through consultation with management. ]]

[[ sh /n ][ Safe Work Practices ]]

Occupational health and safety programs can protect you only when you use safe work practices. Regulations, procedures, signs and other safety measures cannot protect you unless you follow them at all times.

One of the most common causes of industrial accidents is human error which could be caused by lack of proper training, fatigue, carelessness, inappropriate behaviour, poor maintenance of equipment to name just a few of the possible reasons. Another common cause of industrial accidents is failure to remedy hazards that are found on the construction site.

Industrial accidents often involve personal injury and even death, as well as damage to plant and equipment. Industrial accidents often incur very high health costs, personal suffering, loss of income, loss of production, repair and replacement of equipment and reduced business profits.

We will have a more detailed look at safety precautions and safe operating procedures in other chapters of this text. But for now, the following is a brief overview of some safe work practices.

HOUSEKEEPING

The construction site must always be maintained in a safe and orderly condition. Some examples of good housekeeping are:

- access to and from the site should be kept clear

- excess or waste materials should be collected and stored or disposed of properly

- work areas should be kept tidy and free from obstructions or material that may be a trip hazard as well as oil, grease or other substances that may be a slip hazard

- tools, equipment and machines should be maintained in good condition and stored correctly when not in use

- protruding objects such as exposed nails or reinforcing steel should be removed or made safe in an appropriate manner.

EQUIPMENT SAFETY

Hand Tools: Maintain hand tools in a safe working condition. Defective tools should never be used because they can cause injury. For example, if you use a hammer with a loose head it could fly off and hit another worker.

Plant, Equipment and Power Tools: All mechanical equipment is potentially dangerous and must be used with the utmost care. Make sure you follow all safety precautions and operating instructions. They are there for your protection.

Personal Protective Equipment: You must wear protective devices such as a hard hat, goggles or earmuffs when necessary, depending on the equipment you are using and the type of work you are doing. Personal protective equipment must be properly maintained and correctly stored when not in use.

Electrical Equipment: Never use defective electrical equipment and never try to repair defective electrical equipment. If you find any item of electrical equipment to be defective you must report it immediately.

Compressed Air: Never use compressed air in any way that might cause injury or discomfort to anyone on the construction site. Don’t use compressed air to blow dust from your clothes or hair. A blast of compressed air close to your body can enter the bloodstream or intestines and cause serious injury or health problems.

INAPPROPRIATE BEHAVIOUR

Inappropriate behaviour such as practical jokes, showing off or horseplay has no place in a work environment. Someone is usually the ‘butt’ of practical jokes which can result in personal injury or damage to property.

Horseplay on a construction site can be very dangerous. You could fall or be hurt in other ways by stationary objects, moving parts of machines, cutting tools and hot objects, to name just a few examples of safety hazards that become more dangerous when workers fool around on a construction site.

REFLECT & RESPOND

Before leaving this page, think of what you’ve just been reading, and test yourself with these questions.

[[ mc /f ][ Complete this example of good housekeeping / safe work practice “Excess or waste materials …” ][ … should be collected and stored or disposed of properly. ][ * … should be stacked up as near as possible to the site entrance. ][ * … should be buried on-site to reduce clean-up costs. ][ * … should be offered to site workers to take home for odd jobs. ][ Proper procedures must be followed for storage and/or disposal. ]][[ mc /f ][ Complete this example of good housekeeping / safe work practice “Tools, equipment and machinery …” ][ … are maintained in good order. ][ * … are never shared with other workers. ][ * … are always purchased from a reputable supplier. ][ * … are always of the very best quality. ][ Proper maintenance of tools and equipment is an example of good housekeeping. ]][[ mc /f ][ A little bit of fooling around and practical joking is fine on the construction site – true or false? ][ * True – a little laughter is good for on-site relations. ][ False – practical jokes are rarely funny for everyone, and can cause accidents. ][ Fooling around is not good site behaviour. ]]

[[ sh /n ][ Hazard Control ]]

Control of safety and health hazards identified on the construction site can range from complete removal to reducing the effect of the hazard. The control strategies which follow (often referred to as the hierarchy of control) are listed in order of priority or importance.

- Elimination: Depending on the nature of the hazard it could be eliminated by procedures such as complete removal, implementing a new process or redesigning equipment. Elimination is the highest priority control measure.

- Substitution: The offending item could be substituted with a less hazardous material, substance or piece of equipment if it cannot be removed completely.

- Engineering Controls: Engineering controls might involve modifications to tools, equipment and machines to improve guards or suppress noise or vibration. Engineering controls are used if elimination or substitution are not feasible.

- Administrative Controls: Administrative controls could involve improving the level of supervision, job rotation, routine maintenance and training on work methods.

- Personal Protective Equipment: This is the last measure in the hierarchy and is used when all other means of controlling the hazard are not adequate.

REFLECT & RESPOND

Before leaving this page, think of what you’ve just been reading, and test yourself with these questions.

[[ mc /f ][ Which of the following steps should you take first when faced with working with a product that produces hazardous dust: – ][ * Make sure you’re wearing dust masks and coveralls. ][ * Ensure that you have been fully trained in working with the product. ][ * Change your cutting tools for ones that have built-in dust capture. ][ Order an alternative product that doesn’t have the same dust hazard risk. ][ Even though PPE is essential in hazardous evnvironments, working with a safer product is the first control to apply in this situation. ]]

[[ sh /n ][ Personal Protection ]]

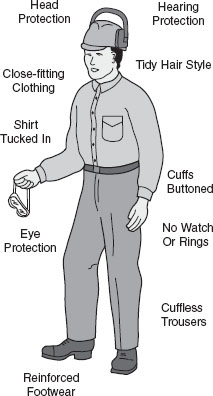

Always wear correct work clothing on the construction site. You must also wear personal protection that suits the work being done. Clothing may vary with climate, however the following gives you a general guide:

- Wear plain, tough clothes that are reasonably close fitting. Loose clothing or unbuttoned overalls can be caught in moving parts of machinery.

- Wear cuffless trousers. Cuffs may cause the wearer to trip or they may catch harmful substances.

- Footwear should be strong and in good repair. Safety footwear has reinforced toe caps to protect against heavy falling objects.

- Long hair should be worn as required by regulations, constrained where necessary by a safety cap or hair net. You could be very seriously injured if your hair is caught in revolving machinery.

- Rings and wrist watches should not be worn, particularly when operating machines. They can be easily caught in moving parts of machines and cause serious injury.

- Personal protective devices such as hard hats, earmuffs, goggles and leather gloves should be worn when necessary, depending on the type of work being done. Rubber soled safety boots provide extra protection from electrical injury.

REFLECT & RESPOND

Before leaving this page, think of what you’ve just been reading, and test yourself with this question.

[[ mr /f ][ Which of the following clothing statements fit with the general guide given above: – ][ * Bricklayers don’t need to wear shirts when working. ][ * Sport shoes are suitable footwear when working in the site office. ][ Jewellery should be removed before going on-site. ][ Rubber soled boots are a must if electrical shock risk exists. ][ * Unbuttoning your shirt on a hot day is ok. ][ * Women can wear their long hair out, but men need to tie it back. ][ Bricklayers need shirts on to prevent sunburn; Sports shoes won’t do if you have to leave the office; Unbuttoning increases risk of getting caught in machinery; All hair needs to be tied back to minimise risk. ]]

[[ sh /n ][ Hazards to Eyesight ]]

Your eyesight is one of your most valuable possessions. You should look after it at all times. On the construction site there are many hazards that could damage your eyes. Most of them are chemical, physical or radiation hazards.

- Chemical Hazards: On a construction site most of the chemicals that could damage your eyesight would be either solvents, protective coatings or adhesives. Where splashing of chemicals could occur you should wear eye protection such as goggles or a face shield if the hazard cannot be completely eliminated by some other means.

- Physical Hazards: Hazards such as airborne dust and particles can enter your eyes and cause irritation, infections or even serious permanent damage. Particles from saws, planers and angle grinders would be among the most common hazards. Hazards that cannot be permanently removed, can be reduced by wearing suitable eye protection.

- Radiation Hazards: Very strong light sources such as arc welders and lasers can be very damaging to your eyes. This type of radiation can also cause long term problems such as cataracts. Strong sunlight, glare and poor lighting can cause eye strain.

REFLECT & RESPOND

Before leaving this page, think of what you’ve just been reading, and test yourself with this question.

[[ mr /f ][ Which of the following substances / situations are a potential eyesight hazard on a construction site? ][ Solvent glues. ][ Bright sunlight. ][ Laser light. ][ Waterproofing sealants. ][ Sawdust particles. ][ * Fresh water. ][ Except for water, all of these things can potentially injure our eyes at work. ]]

[[ sh /n ][ Eyesight Protection ]]

Protective equipment such as goggles or face shields should be used with other methods of hazard control or if other methods cannot be used. Protective devices can only work if you fit them properly and wear them correctly and keep them in good condition. Keep lenses clean and methods of fitting or adjustment (such as elastic bands) in good condition. Your eyesight is a vital part of your everyday living as well as on the construction site. Always, without fail, protect your eyes from damage that can be caused by chemicals, radiation and airborne foreign bodies.

EYE PROTECTION EQUIPMENT

You should wear safety glasses, goggles or face shields when necessary, in areas of the construction site where small flying particles, dust, hot metals or splashing of dangerous liquids may occur.

Safety Spectacles provide frontal protection from impact injury. Side guards can be fitted where side entry protection is required.

Goggles provide both front and side protection. Goggles have the advantage that you can wear them over normal glasses.

Face Shields provide full face protection but are easily scratched and should be replaced when visibility is reduced.

Tinted Lenses of various types provide protection from radiation. These can range from face shields for welding to safety sunglasses for outdoor workers.

Most accidents can be prevented by removing likely causes. Your employer can try to control hazards on the construction site but you must behave and work safely at all times, and where possible, try to prevent dangerous conditions developing. Wearing eye protection when necessary is part of your OH&S responsibility.

REFLECT & RESPOND

Before leaving this page, think of what you’ve just been reading, and test yourself with this question.

[[ mr /f ][ Which of the following statements about use of eye protection makes sense? ][ Sunglasses should be worn outside to minimise radiation risk. ][ Tinted glasses should be worn behind welding masks. ][ Face shields should be replaced when visibility is reduced. ][ Side guards are essential to minimise splash and particle intrusion. ][ * If you wear a safety shield, you don’t need to wear safety glasses as well. ][ * Safety goggles will prevent all kinds of eye injuries. ][ Safety shield wearers should also wear glasses, for when the shield is up; Goggles won’t protect you against radiation hazards. ]]

[[ sh /n ][ Hearing Protection ]]

Noise is sometimes described as any unwanted or damaging sound in the workplace. It can vary from low levels of nuisance noise (e.g. enough to stop you using a telephone comfortably) to very loud industrial noise that could seriously damage your hearing.

CAUSES OF WORKPLACE NOISE

High noise levels can usually be found wherever plant, equipment, tools, and machines are used. The noise is produced by such things as motors, moving mechanical parts, compressed air, the impact of one surface on another and cutting or shaping materials.

THE HIERARCHY OF NOISE CONTROL

If you can’t talk to someone without raising your voice when standing face to face, the noise is probably at a dangerously high level. Noise protection could be provided in the following ways:

- changes to machines or equipment that reduce noise levels or remove the noise hazard completely

- isolation of the noisy machines and equipment

- installation of sound proofing or dampening

- administrative controls that reduce exposure time to excessive noise

- provision of personal protective equipment such as earmuffs or plugs.

LIMITATIONS OF PERSONAL HEARING PROTECTION

Personal hearing protection devices are used only when all other methods of noise control are not adequate. Hearing protectors such as disposable earplugs, re-useable ear plugs and earmuffs can be effective within certain limits:

- earplugs must be properly inserted into your ear canals

- earmuffs must be fitted snugly over your ears for maximum comfort and protection

- if you wear glasses you could f ind that earmuffs do not fit properly (you may need to wear a different type of ear protection)

- ear protection must be worn all of the time in high noise areas

- protection devices must be properly maintained

- hearing protectors may not be very effective against sustained high levels of impact noise.

Some construction sites can be very noisy. Long exposure to high levels of industrial noise could result in some permanent loss of hearing. Don’t risk your hearing. Use proper hearing protection when necessary.

CONCEPT OF DAILY NOISE DOSE

Sound pressure levels are measured on a scale called the decibel scale. Your ear can detect a range of noise levels from zero decibels (threshold of hearing) to 130 decibels (threshold of pain) and beyond. Noise levels beyond 130 decibels can cause immediate and permanent hearing damage.

A decibel scale, dB(A), is used for measuring workplace noise because it represents the way our ears respond to different levels of sound. Daily Noise Dose is the term used in industry to describe a worker’s daily exposure to noise. The tables which follow give some examples of noise levels on the dB(A) scale.

ACCEPTABLE DAILY NOISE DOSE

The National Standard and Code of Practice for Occupational Noise recommends 85dB(A) over eight hours equivalent as the maximum daily noise dose that workers should be exposed to. Most states have adopted this standard in their occupational health and safety legislation. The nature of the dB(A) scale means that, for example, a noise level of 90dB(A) would be ten times louder than a noise level of 80dB(A).

The table on the right lists approximate noise levels for some familiar sources of noise. The table shows Source Level – dB(A) that a rock group could be ten times louder than a pneumatic drill or the family car could be ten times louder than a normal conversation between two people.

Exposure to the standard 85 decibels for a period of eight hours gives a worker a Daily Noise Dose of 0.32 measured on a daily noise dose scale. (Refer to the table on the next page). If someone is exposed to a Daily Noise Dose over 0.32 for a long time permanent hearing loss may occur.

The table on the left shows that for a decrease of only three decibels in noise level the Daily Noise Dose is halved, therefore the maximum daily exposure time could be doubled at safe levels. Industrial deafness is caused by exposure to high noise levels over a period of time. The table shows that, for example, at a noise level of 82 decibels permanent damage could occur if exposed for more than 16 hours a day over a period of time.

PROTECTION PROCEDURES

Noise control procedures in the workplace can be summarised as:

- reducing the level of noise produced in the workplace by modifying, isolating or sound proofing offending plant and equipment where possible

- reducing the level of noise received through enclosure (isolating the worker)

- reducing the length of exposure to noise by administrative procedures such as job rotation and changing job schedules

- wearing personal protective equipment such as earmuffs or earplugs to reduce the noise level received by the worker.

The choice between earmuffs or earplugs and the various types available will depend on:

- personal preference

- work conditions

- noise reduction required.

Most good quality hearing protection devices are rated to provide a certain noise level reduction usually in the range 20dB(A) to 40dB(A). If, for example, the noise level produced by a pneumatic drill is 100dB(A), you would have a Daily Noise Dose of 10.00 allowing a maximum daily exposure time of only 15 minutes (see previous table).

If you use earmuffs that are rated at 20dB(A) the noise level actually heard is reduced to 80dB(A), well below the acceptable noise level of 85 decibels. This would allow you to work safely at that location for a full day.

REFLECT & RESPOND

Before leaving this page, think of what you’ve just been reading, and test yourself with these questions.

[[ mr /f ][ How can you control the risk to hearing when working in noisy environments? ][ * Turn noisy machines off when having a conversation. ][ Replace noisy machinery with quieter units. ][ Isolate the noisy machines and equipment. ][ Install sound proofing or dampening. ][ Rotate workers to minimise exposure to excessive noise. ][ Provide PPE such as earmuffs or plugs. ][ Turning machines off to have a conversation is not productive – have the converstaion elsewhere. ]][[ mc /f ][ Why are earplugs considered as a last line of hearing protection? ][ Earplugs block audible warnings as well as problem noise. ][ * Earplugs aren’t hygeinic. ][ * Earplugs can be very uncomfortable. ][ * Ear plugs and earmuffs cause overheating. ][ Earplugs reduce your safety because you can’t hear warning calls as clearly. ]][[ mc /f ][ You’re front row at a concert listening to your favourite heavy metal band. How long can you stay there for before risking damage to your hearing? ][ * Less than 1 hour. ][ * Less than 30 minutes. ][ Less than 10 minutes. ][ * Less than 2 hours. ][ By the numbers, 10 minutes at that volume is too long. ]]

[[ sh /n ][ Respiratory Protection ]]

You should wear respiratory protection whenever the concentration of airborne dust or fumes could present a health hazard.

Dust masks should be worn on the construction site when dust from earth-moving, sanding or clean-up operations may be concentrated enough to present a health hazard.

Respirators should always be worn in situations where toxic fumes could be inhaled. Hazardous fumes may be encountered when using products such as volatile solvents, protective coatings, adhesives and acids.

REFLECT & RESPOND

Before leaving this page, think of what you’ve just been reading, and test yourself with this question.

[[ mc /f ][ Which of the following statements doesn’t make sense: – ][ Wearing a dust mask will protect you from solvent fumes. ][ * Dust masks should always be worn when grinding concrete. ][ * Respirators are essential when working with adhesives and acids. ][ * Sawdust will be filtered with a dust mask. ][ Solvent fumes will go straight through a dust mask. ]]

[[ sh /n ][ Safety Clothing and Footwear ]]

Steel capped boots are the preferred footwear for all workers on the construction site. The reinforced toecaps protect the feet from heavy falling objects as well as from accidentally kicking hard objects at foot level.

Safety caps or hard hats are made from high impact plastic material and provide head protection against objects falling from above, for example, materials or tools falling from a scaffold or overhead work platform.

Gloves should be worn, for example, when handling sharp, hot or very rough objects or materials that might damage your hands. There are also several types of safety gloves available for purposes such as handling chemicals.

High visibility clothing such as vests, jackets and overalls can be worn on the construction site to provide additional protection from moving vehicles, machines and equipment.

The driver of a truck, for example, has a much better chance of seeing you if you are dressed in a yellow vest rather than dark clothing. Most styles of safety clothing also feature reflective strips that improve visibility.

REFLECT & RESPOND

Before leaving this page, think of what you’ve just been reading, and test yourself with these questions.

[[ mr /f ][ What does the well dressed construction worker wear these days? ][ * A high-vis vest over a short sleeved t-shirt and shorts. ][ A High-vis jacket over cuffless work trousers. ][ A bright coloured hard hat and safety glasses. ][ A wide-brim hard hat with sunglasses. ][ * Leather gloves and boots with leather soles. ][ Workboots need to have high-grip rubber soles; t-shirt and shorts aren’t very protective. ]]

[[ sh /n ][ Safety Signs ]]

Safety signs give you a graphic reminder of safety requirements on the construction site. Safety signs should always be placed in an obvious position as close as possible to where the hazard or safety requirement exists.

REGULATORY MANDATORY SIGNS

These signs, such as the examples illustrated below, are usually blue and white and are used where there is a compulsory safety requirement.

For example, the head protection sign would be placed in an area where overhead work is being carried out and the respiratory protection sign could be displayed where protective coatings are being sprayed.

REGULATORY PROHIBITION SIGNS

These signs consist of a red circle with oblique bar over a black image. Regulatory prohibition signs are used where an activity is not allowed for health or safety reasons. For example, the ‘No Smoking’ sign on the right could be used in any location where a spark may be a hazard, such as near flammable liquids.

Safety signs sometimes combine a symbol and a written instruction or message where additional safety information is required as in the three examples below.

HAZARD WARNING SIGNS

Hazard warning signs such as the overhead crane sign on the right consist of a black symbol in a black triangle on a yellow background. They can also be used in conjunction with a written instruction or message to provide extra impact or information as in the examples below.

EMERGENCY INFORMATION SIGNS

Emergency information signs are green and white in colour and should be placed at the location where the emergency information is required. For example, a first aid sign could be placed where the construction site first aid kit is located.

Emergency exit signs are usually luminous (glow in the dark). The emergency exit symbol is often used with an EXIT sign as shown below. Building and fire regulations in some states require that illuminated EXIT signs with backup battery power supply must be installed in industrial buildings.

DANGER SIGNS

Danger signs are red, black and white in colour. An example is shown on the right. The word DANGER is white against a red oval background. The remainder can be worded as required to suit any situation where a hazard danger exists in the workplace.

DANGEROUS GOODS SIGNS

Dangerous goods are grouped into nine different classes, each with its own distinctive diamond shaped sign or label. These labels must be displayed when dangerous goods are stored or transported. Composite signs showing all classes stored should be located at points of entry to a building, room or area where dangerous goods are stored.

Labels have four components which help to make them highly visible and different from each other. A typical example is shown on the right.

- Symbol – a visual image of the hazard (flame).

- Description – the words ‘flammable liquid’.

- Number – class code for flammable liquids (3).

- Colour – black type and symbol on coloured background (red).

Classes are coded from 1 to 9 as follows:

- Class 1 – Explosives

- Class 2 – Gases

- Class 3 – Flammable Liquids

- Class 4 – Other Flammable Substances

- Class 5 – Oxidising Substances

- Class 6 – Toxic or Infectious Substances

- Class 7 – Radioactive Substances

- Class 8 – Corrosive Substances

- Class 9 – Miscellaneous Dangerous Substances

Examples are shown below with their risk descriptions.

Subsidiary risk labels are used where a material presents more than one hazardous property. A subsidiary risk label does not display the class code. Examples with their risk descriptions are Class 1 – Projectile hazard but Class 4 – Substances liable shown on the right.

Subdivisions of class labels may display a different symbol or an extended number as illustrated by the three examples on the left.

A United Nations number (UN number) applies to a specific dangerous substance and is used worldwide, particularly on freight containers. The toxic substance label on the right applies to the specific substance indicated by UN number 2516.

HAZCHEM SIGNS

Hazchem signs, which are red on a white background, show that hazardous substances are stored on the site. The HAZCHEM signs illustrated are outer warning signs that should be clearly displayed at every entrance to a workplace. These signs are used together with with dangerous goods signs.

HAZCHEM CODE

The HAZCHEM code is a two or three digit alpha-numeric symbol which indicates response procedures that should be followed in an emergency.

A typical warning sign that would be used where different classes of goods are stored is illustrated on the left.

The dangerous goods class diamonds show the hazardous nature of the goods and the HAZCHEM code indicates the action that would be required in an emergency.

Interpretation : The table on the right is the key to interpreting the code in a warning sign. The number indicates which of the fire 3 fighting methods should be used; jets, fog, foam or dry agent.

Note: In the absence of fog equipment, a fine spray may be used. Also, a higher number may be used but never a lower for FIRE only DILUTE number. The first letter in the middle of the code is T BA for FIRE only taken from the column on the left of the table. The procedure indicated by the letter X is read across the table from left to right. Note: The letter V in the second column for FIRE only means that a violent reaction or explosion Z BA may occur under certain conditions. In the for FIRE only third column, BA means that breathing Consider Evacuation apparatus and PVC gloves should be worn. E

FULL means that full body protective clothing and gear should be used. This includes breathing apparatus, PVC gloves, rubber boots and a chemical splash outfit. ‘BA for f ire only’ relates to the white letters in the first column. The right hand column indicates whether a spill can be diluted with large quantities of water or contained by any means available.

The second letter (E) indicates that evacuation should be considered. If evacuation is not a consideration there would be only a number and one letter in the code.

Example: HAZCHEM code 4WE would be interpreted as follows:

- dry agent only to be used

- violent reaction or explosion could occur

- full body protective clothing and gear should be used

- the spill should be contained by any means available

- evacuation should be considered.

TRAFFIC SIGNS

Signage is often used on a large construction site to direct traffic around the area. Traffic could consist of a variety of delivery vehicles, sub-contractors vehicles, concrete trucks, earth-moving machines and other equipment. As well as giving directions, traffic signs can perform an important safety role by restricting moving vehicles to defined areas or roadways on the construction site.

REFLECT & RESPOND

Before leaving this page, think of what you’ve just been reading, and test yourself with these questions.

[[ mr /f ][ Which of the following statements about safety signs are correct: – ][ Mandatory signs are usually blue and white. ][ Prohibition signs usually have a red circle with a red bar over a black image. ][ Hazard warning signs usually have a black triangle on a yellow background. ][ * Emergency information signs are black and white in colour. ][ Danger signs are red, black and white in colour. ][ Emergency information signs are usually green and white. ]][[ mc /f ][ What kind of dangerous goods have a warning sign with a skull and cross-bones on it? ][ * Class 3 – Flammable liquids. ][ * Class 1 – Explosives. ][ Class 6 – Toxic substances. ][ * Class 7 – Radioactive substances. ][ Toxic (poisonous) substances carry the skull and cross-bones. ]][[ mc /f ][ What kind of dangerous substances label should be found on bottles of acid used for etching metal? ][ * Class 1 – Explosives. ][ * Class 3 – Flammable liquids. ][ * Class 5 – Oxidising substances. ][ Class 8 – Corrosive substances. ][ Acids corrode (etch) metals. ]][[ mr /f ][ What does HAZCHEM Code 3YE tell you about the appropriate response in case of emergency? ][ Foam should be used to fight the fire. ][ * Dry agent should be used to fight the fire. ][ A violent reaction may occur. ][ * Full body PPE should be worn. ][ Breathing apparatus and PVC gloves should be worn. ][ Evacuation may be advisable. ][ Foam rather than dry agent should be used; Breathing apparatus and PVC gloves in preference to full body PPE. ]]

[[ sh /n ][ Fire Prevention and Control ]]

Fire prevention is the responsibility of everyone on the construction site. The best method of fire prevention is to obey all fire safety signs, regulations and precautions that apply to the work area.

The following must all be present before a fire can start:

- oxygen

- fuel

- heat.

Fires can be prevented by removing any one of these. Fuel is anything that will burn and may be in the form of a solid, liquid or gas. The heat required to start a fire will depend on the type of fuel and how easy it burns. The sparks produced inside a power tool or a discarded cigarette butt could start a fire.

Fuel and the heat source can usually be removed to prevent a fire but oxygen in the air cannot usually be eliminated to prevent a fire starting. However, the oxygen supply can be cut off by using fire blankets or fire extinguishers which contain carbon dioxide gas, foam or chemicals. For some fires, water can be used to cool or eliminate the heat source.

FIRE SAFETY PRECAUTIONS

- Observe all safety signs, safety rules or regulations

- be aware of the properties of flammable materials used in the workplace

- dispose of all unnecessary combustible materials in the proper manner

- safely store and carefully handle all necessary combustible materials

- keep combustible materials away from sources of heat

- never use electrical equipment near flammable vapours or gases

- use volatile liquids such as solvents and paints only where there is good ventilation and well clear of any heat sources

- report any detected gas leaks

- clean up spillages of flammable liquids immediately

- remove and wash clothing that becomes saturated with flammable liquid.

CLASSIFICATION OF FIRES

Fires are classified according to the type of fuel being burnt:

Class A fires involve common burnable materials such as wood, cloth, paper and packaging materials.

Class B fires involve flammable liquids such as petrol, kerosene, oil, grease, fat, wax, paint, solvents and some polishes.

Class C fires involve flammable gases such as LP gas, butane and acetylene.

Class D fires involve metals.

While there is no formal classification for electrical fires, a fire extinguisher sign will often include (E)to show that it is suitable for electrical fires.

EMERGENCY EQUIPMENT

All fire fighting equipment should be clearly marked with the correct signs so they can be quickly located if there is a fire. Examples of some of these signs are shown below.

FIRE EXTINGUISHERS

Fire extinguishers are colour coded according to the fire fighting material in them. Different fire fighting materials are used for different types of fires. The triangular colour coded signs below are placed near f ire extinguishers. The signs are red with a different coloured ‘target’ to indicate the type of extinguisher.

Other signs which list some of the fires an extinguisher can be used on (or should not be used on) are shown below.

Water extinguishers can be used for wood, paper and rubbish fires but should not be used for electrical or flammable liquid fires.

Foam extinguishers can be used for oil fires and flammable liquid fires but should not be used for electrical fires.

CO2 (Carbon Dioxide) extinguishers can be used for paint, oil, electrical and other flammable liquid fires.

Dry Chemical – Class B extinguishers can be used for oil, flammable liquid and electrical fires.

Dry Chemical – Class A:B extinguishers can be used for paper, wood, textile, oil, flammable liquid and electrical fires.

Wet Chemical extinguishers can be used for animal fat and vegetable oil fires but not for electrical fires.

REFLECT & RESPOND

Before leaving this page, think of what you’ve just been reading, and test yourself with these questions.

[[ mr /f ][ What three things do you need for a fire to start? ][ Oxygen. ][ * A box of matches. ][ Fuel. ][ Heat. ][ Not all fires are started with matches. ]][[ mc /f ][ What class of fire will be fuelled by chemical solvents? ][ * A ][ B ][ * C ][ * D ][ * S ][ Class B applies to solvent-based fires. ]][[ mc /f ][ What colour code applies to a foam-based fire extinguisher? ][ * Red. ][ * White. ][ Blue. ][ * Green. ][ Foam extinguishers are colour coded blue. ]][[ mc /f ][ What colour of extinguisher should be used on an electrical fire? ][ * Red extinguisher. ][ * Yellow extinguisher. ][ * White extinguisher. ][ Black extinguisher. ][ Black (CO2) extinguishers are best suited to electrical fires. ]]

[[ sh /n ][ Evacuation Procedures ]]

We need evacuation and emergency procedures to protect the lives of people in the area. Workplaces and schools have evacuation procedures that must be followed when a fire or other emergency occurs. These procedures are designed to suit the layout of the site and ensure the orderly movement of people to a safe location.

Other evacuation procedures aim to minimise damage to buildings and equipment when there is a fire. These procedures should be carried out only when it is not dangerous and could include shutting down machines, turning off power, turning off gas and closing doors or windows to reduce air supply.

Some emergency procedures may not be the responsibility of students. However, it is the responsibility of all students and workers alike to fully understand evacuation procedures and to follow them whenever necessary.

EMERGENCY SERVICES

Emergency services such as fire, ambulance and police can be quickly contacted by dialling 000 when an emergency occurs. Larger organisations have trained safety officers who should be informed immediately. Safety officers are usually qualified to administer first aid when accidents occur on a construction site.

Workplaces and schools will generally have standard procedures for contacting emergency personnel. These procedures are designed to make sure that emergency personnel are contacted quickly and without fail.

For this reason it is very important that standard procedures are understood by everyone in the school or on the construction site and that these procedures are followed when there is an emergency.

REFLECT & RESPOND

Before leaving this page, think of what you’ve just been reading, and test yourself with these questions.

[[ mr /f ][ Which of the following statements about evacuation and emergency procedures are correct: – ][ Evacuations are designed to protect lives. ][ * Evacuations minimise damage to buildings and equipment. ][ Emergency services are contactable on 000. ][ * Don’t waste time reporting emergencies to the safety officer. ][ Everyone must follow stated emergency procedures. ][ Emergency personnel should be contacted asap. ][ Evacuations minimise risk to personnel, not structures; Safety officers should be notified asap. ]]

[[ sh /n ][ Handling Hazardous Material ]]

Forms Of Hazardous Material

Hazardous materials found on the construction site are usually chemicals which can be in the form of solids, liquids or gases.

Solids can be in the form of a solid mass or small particles such as granules, dust and powder. Smoke and fumes can also contain small particles of solid material.

Liquid chemicals such as solvents, protective coatings and cleaning agents are relatively safe if used and stored correctly. Volatile liquid chemicals are a serious hazard when their vapours come into contact with a heat source.

Gases are a natural state of matter where atoms or molecules are not bonded together as they are in solid or liquid forms. Gases can be a hazard when they are poisonous, compressed and stored in tanks, particularly when allowed to escape into the air.

PHYSICAL HAZARDS

Physical hazards presented by chemical materials usually involve combustion, explosion and implosion.

Combustion results in fire which requires fuel, a heat source and oxygen to be present. The removal of any one of these elements will cause a fire to be extinguished.

Explosion of chemical compounds can occur when an unstable material breaks down to form a gas which, if contained, can result in a huge increase in pressure. Physical explosions are caused by the sudden formation of very large quantities of vapour caused by a liquid coming into contact with a source of heat.

Implosion can occur in a closed vessel when there is a reduction in pressure. Implosions caused by the cooling of heated contents in a closed vessel or pumping liquids out of sealed vessels are among the most common.

HEALTH HAZARDS AND EFFECTS

Chemicals may enter the body by ingestion (swallowing), inhalation (breathing in) and absorption through the skin. Chemicals entering the body can cause serious health effects.

Asphyxiation is caused by lowering of the oxygen level in the breathable air or by inhaling toxic gases which prevent the body taking up oxygen. Lack of oxygen can cause rapid heart beat, dizziness and headache.

Toxicity or poisoning is the most serious health hazard presented by industrial chemicals. The effects of poisoning could range from short term vomiting and headaches to chronic liver and kidney damage, brain damage and even death.

Burns from corrosive chemicals such as acids usually happen when there is contact with the skin. If splashed in the eyes, corrosive chemicals cause serious eye damage or even blindness. Corrosive materials should be handled in a well ventilated area with suitable hand and face protection being worn.

Irritation from irritant chemicals can result in inflammation of the respiratory tract, digestive tract, eyes or skin which can cause bronchitis or dermatitis. Irritants include substances such as cement dust, epoxy resins, organic solvents and strong detergents.

Allergic reactions can be caused by chemical substances which are called sensitisers. Reactions can be in the form of skin rash or dermatitis and even asthma attacks which may not occur for some time after exposure.

Cancer causing substances (carcinogens) present a very serious health hazard in some industries. They can cause malignant tumors which spread to other parts of the body. Medical researchers are continually trying to identify carcinogens in the food we eat and in chemical substances used in industry.

PROTECTIVE HANDLING STRATEGIES

Careful handling is very important when chemicals and other dangerous substances are used on the construction site. Understanding how chemicals enter the body is the first step in developing a handling strategy to protect yourself.

Chemicals can enter the body by any of the following:

- breathed in and absorbed through the lungs

- swallowed and absorbed through the stomach

- absorbed directly through the skin.

Inhaling (breathing in) is the fastest way that a dangerous substance can enter your body. The substance is taken directly to the lungs and quickly absorbed through the air sacs into the blood stream.

Swallowing dangerous substances can occur if normal hygiene, such as washing hands after handling chemicals, is not followed.

Absorption through the skin can occur with many dangerous substances. These chemicals get through the skin into the blood stream and travel to the vital organs (liver, kidneys, heart, brain, etc), where they can cause short and long term damage.

HIERARCHY OF CONTROL

Hierarchy of control principles can be used when dangerous substances are handled in the workplace. The following procedures should be used in conjunction with Material Safety Data Sheets:

- determine which substances are dangerous

- consider replacing dangerous substances with alternatives that are not dangerous or are less dangerous

- avoid contact with dangerous substances wherever possible

- understand the effects and dangers involved

- follow manufacturers’ instructions carefully

- follow precautions listed in the MSDS (e.g. ventilation)

- always use protective equipment and clothing

- wash thoroughly after handling chemicals even if protective equipment is used

- know the correct first aid procedure in case of accident

- never eat or drink near dangerous substances.

REFLECT & RESPOND

Before leaving this page, think of what you’ve just been reading, and test yourself with these questions.

[[ mr /f ][ Hazardous materials come in three forms on a construction site – what are they? ][ Solids. ][ Liquids. ][ Gases. ][ * Plasma. ][ hazardous materials can be supplied as solids, liquids and gases. ]][[ mr /f ][ What physical hazards can be presented by chemicals on the site? ][ Combustion. ][ Explosion. ][ Implosion. ][ * Wetting. ][ Getting wet may occasional happen on site, but wouldn’t normally be classed as a chemical hazard. ]][[ mc /s /f ][ How can dangerous chemicals find their way into your body? ][ * Breathing in the fumes. ][ * Swallowing it. ][ * Getting it on your skin. ][ All of the above. ][ Contacting chemicals in any way exposes us to a risk. ]]

[[ sh /n ][ Manual Handling ]]

Many industrial injuries are caused by incorrect manual handling. Spinal injuries, muscle injuries and hernias can be caused by incorrectly lifting a heavy load or even light loads over a long period of time.

SPINAL INJURIES

Spinal injuries usually involve damage of the inter-vertebral discs which are pads of fibrous tissue that act as cushions or shock absorbers between the vertebrae of the spine. Bending the back applies a pinching effect on these discs.

Lifting a load with the spine bent increases this pinching effect and can even cause a disc to burst resulting in a painful injury.

Lifting with the back straight distributes compression over the spinal column. Twisting the spine while carrying a load can also result in a serious injury.

MUSCULAR INJURIES

Injuries to muscles are often caused by incorrect posture when lifting; for example, using back muscles to support the body and the load in a bent over position.

HERNIAS

A hernia occurs when part of the intestine protrudes through a rupture or tear in the wall of the abdomen. Bending over from the waist compresses the intestines. Lifting a load at the same time increases that pressure and therefore increases the chance of a rupture occurring.

LIFTING TECHNIQUE

You can avoid these injuries if you use a correct lifting technique. Bend the knees, not the back and never twist the body when you are lifting or carrying a load. When you are lowering a load, bend the knees and keep the back straight.

This is a safe method for lifting a load:

Consider the load: Assess its size, shape and weight. If necessary ask someone to help you.

Position the feet: Your feet should be placed apart in a comfortable position with one foot in front of the other as close as possible to the load.

Assume the lifting position: With the upper part of your body erect, keep the back straight and bend your knees.

Keep your head up and chin in as shown in the illustration on the right. This will help to keep your back straight.

Grip the load: Get a good grip of the load using the full length of your fingers as well as part of the palms of your hands. Depending on the shape of Upright posture the load, your hands could be placed on diagonally opposite corners.

Lift the load: Keeping your upper body and head erect, chin in, back straight and arms close to your body, lift the load by straightening your legs. Hold the load close to your body.

Lifting very heavy loads manually should be Lift with the legs considered only as a last resort. Use a mechanical aid such as a fork lift or pallet trolley wherever the action of lifting or carrying might cause injury.

REFLECT & RESPOND

Before leaving this page, think of what you’ve just been reading, and test yourself with these questions.

[[ mr /f ][ What kinds of injuries can be caused by incorrect manual handling? ][ * scratches on arms and legs. ][ Hernias. ][ Crushed spinal discs. ][ Muscle damage. ][ * Eye and ear damage. ][ Hernias and spinal and muscle damage can be caused by incorrect manual handling. ]][[ mc /f ][ Which of the following is the recommended technique for lifting heavy loads: – ][ Back straight, knees bent. ][ * Feet together, legs straight. ][ * Legs straight, back bent. ][ * Bend the knees, bend the back. ][ Lift with your back straightand your knees bent. ]][[ mc /s /f ][ How should your feet be positioned when preparing to lift a heavy load? ][ Apart and in a comfortable position. ][ * As far back from the load as possible. ][ * Feet should be side-by-side. ][ * All of the above. ][ Your feet should be apart and in a comfortable position, one foot in front of the other, and as close as possible to the load. ]][[ mr /f ][ Which of the following statements reflect good technique when lifting a load? ][ Keep your upper body erect. ][ Keep your head erect with your chin tucked in. ][ Keep your back straight. ][ * Keep your arms away from your body. ][ Lift by straightening your legs. ][ Hold the load close to your body. ][ * Breathe out as you lift. ][ Everything except the statements about arms and breathing, reflects good technique. ]]

[[ sh /n ][ Assesssing Risks & Controlling Hazards ]]

A hazard is anything on the construction site that could cause an accident or contribute to an accident occurring.

Risk is the degree of probability that an accident could occur on the construction site because a certain hazard exists.

While hazards exist, there is risk of accidents occurring. There is always some element of risk present in the workplace, in the home, on the street or in any public place. Some risk simply cannot be avoided. However, identifying hazards and assessing risks can help in controlling hazards on the construction site and reducing the chances of accidents occurring.

HAZARD TYPES

Hazards can be described as acute hazards or chronic hazards.

Acute hazards have an instant effect and are generally easy to identify and simple to control; for example, oil spilt on the floor or an unguarded machine. Control can be as simple as cleaning up oil spills or fitting a guard on the machine.

Chronic hazards are often slow to take effect and may exist unnoticed for a long time. For example, the cancer causing effects of breathing in tiny asbestos fibres was not known for many years, with the result that many workers in asbestos mines and the building industry were badly affected.

Strain injuries which may be caused by repeating the same physical action constantly over a long period of time, could also be classified as resulting from a chronic hazard. Chronic hazards are usually hard to identify until the effects begin to show.

HAZARD GROUPS IN THE WORKPLACE

Classifying hazards into the following groups can help management understand the nature of hazards on the construction site and then work out how to control them:

Physical hazards include noise, airborne particles, unguarded machines, obstacles in work areas, vibration, electrical hazards, f ire, explosion, poor lighting, etc.

Chemical hazards include fumes, vapour, gases, dust, volatile liquids, poisons, etc.

Ergonomic hazards can result from poor design of tools, equipment and furniture that may cause discomfort or injury to the operator over a period of time. Manual handling techniques and task procedures might also present ergonomic hazards.

Radiation hazards may exist in the workplace where equipment emits microwaves, ultra-violet, infra-red, laser, gamma and x-rays.

HAZARD IDENTIFICATION

Before hazards can be eliminated or controlled they must be identified so that remedial action can be taken.

Safety inspections: Identification of hazards in the workplace could result from regular inspections which are part of an on-going occupational health and safety program or from observation by all workers during the course of normal work activities.

Everyone on the construction site is therefore responsible for identifying and reporting hazards.

Safety inspection checklists which broadly cover all possible hazard areas at the construction site could be a part of regular safety inspections. Inspection checklists could also be made for particular items on the construction site so that a more detailed listing of potential hazards could be included.

For example, a checklist for plant would list different machines and items of equipment so that hazards such as a missing machine guard could be accurately identified, reported and then fixed. This would usually involve filling out a hazard report form.

Hazard report forms are usually designed to suit occupational health and safety procedures which have been adopted by the company. Details of the hazard are recorded and then reported to management for risk assessment and where necessary, remedial action.

RISK ASSESSMENT

The purpose of risk assessment is to work out which hazards require the most urgent remedial action. The following is a simple method for assessing risk and deciding which hazards are the most dangerous:

For each of the identified hazards:

- Estimate the likelihood of an accident occurring, keeping in mind existing control measures. A descriptive scale such as: very likely, likely, unlikely, very unlikely, could be used.

- Estimate the consequences of an accident occurring, keeping in mind existing control measures. A descriptive scale such as: death or permanent disablement, serious injury, casualty treatment, minor injury, could be used.

- Combine the estimates of likelihood and consequences and allocate a rating for the risk.

For example, the highest rating would be given to a hazard where ‘the risk of death or permanent disablement is very likely’. The lowest rating would be given to a hazard where even ‘the risk of minor injury is very unlikely’.

CONTROL MEASURES

When risks have been assessed, remedial action or control measures may be necessary to remove the hazard where possible or to reduce the risk. Refer to pages 8, 11, 13 and 27 for information about the hierarchy of control.

REFLECT & RESPOND

Before leaving this page, think of what you’ve just been reading, and test yourself with these questions.

[[ mr /f ][ Which of the following are examples of the results of acute workplace hazards: – ][ * Repetitive strain injury (RSI). ][ * Asbestosis. ][ A broken arm from from tripping and falling. ][ A sprained ankle from slipping. ][ RSI and asbestosis are the results of chronic, not acute hazards. ]][[ tr /f ][ Complete the statement “Hazards are anything on a site that could __________ to an accident occurring.” ][ contribute ][ Contribute ][ CONTRIBUTE ][ … that could contribute to an accident … ]][[ mc /f ][ A cable lying across the floor of a workshop would be considered a hazard. What type? ][ An acute hazard. ][ * A chronic hazard. ][ This is an acute hazard. ]][[ mc /f ][ Who is responsible for identifying and reporting hazards on a construction site? ][ Construction workers. ][ Supervisors. ][ WHS Inspectors. ][ Everyone on the site. ][ Everyone is responsible for hazard identification and reporting. ]][[ mc /f ][ All hazards on a construction site have to be dealt with equally urgently – true or false? ][ * True – any and every hazard on the construction site is a problem. ][ False – hazards that have the highest risk of serious injury should be dealt with first. ][ High-risk hazards should always be the first priority for risk minimisation. ]]

[[ sh /n ][ Emergency Action ]]

When accidents occur on the construction site emergency action may be required. If you are at the scene of an accident it could be up to you to take some form of emergency action. However, if first aid is necessary, it should generally be administered by a qualified person. If there is a trained first aid officer on the site that person should be notified of the accident as quickly as possible.

EMERGENCY ACTION PRINCIPLES

The four emergency action principles listed below are generally accepted guides for action in an emergency situation. Having a basic understanding of these principles may help you to assist in an emergency situation.

Survey The Scene

Make sure there are no dangers to people at the accident scene. Examples of dangers that may be present are; live electrical equipment, fallen power lines, traffic, fire, toxic fumes, etc.

Primary Survey

A primary survey of the injured person could be carried out by the site first aid officer. This involves checking the following:

- Conscious state: If the person is unconscious the ambulance should be called immediately.

- Airway: An unconscious person should be turned on the side and the mouth cleared of any foreign material.

- Breathing: If breathing normally, an unconscious person should be kept on the side, with the head tilted backward, jaw supported, and face slightly downward to keep the airway open. If not breathing, the person should be quickly turned on the back and expired air resuscitation commenced immediately.

- Circulation: The pulse should be checked. If the heart has stopped the person will need CPR (cardiopulmonary resuscitation). If the person is breathing, the heart is beating and blood is being circulated.

- Severe bleeding: A quick check from head to toe should reveal any signs of external bleeding. Severe bleeding must be stopped as quickly as possible by applying pressure.

Call Emergency Personnel

If the accident appears serious enough emergency personnel should be called straight away.

- If nobody at the scene of the accident has a mobile phone, someone should get to the nearest telephone as quickly as possible while another person stays with the casualty.

- The caller should ring 000 and give exact location (correct street address and location on the construction site), information about the accident, condition of the injured person and any first aid given.

Secondary Survey

If any life threatening conditions are found during the primary survey, time should not be wasted with a secondary survey. The airway, breathing and circulation should be checked regularly while attending to the life threatening conditions.

A secondary survey of the injured person could provide information that might be helpful to emergency personnel when they arrive at the accident scene. A secondary survey generally involves asking if the person is in pain, as well as asking about existing medical conditions and other less obvious injuries.

REPORTING ACCIDENTS

Employees are insured by their employer against workplace related injury and disease through a Work Cover or Workers Compensation authority in each state and the Commonwealth of Australia. Accidents which result in injury or death must be reported to these authorities.

State Reporting

Each state Work Cover or Workers Compensation authority has its own reporting method which requires details of a workplace accident to be reported on a special form either as a hard copy or electronically via the internet.

National Reporting

Workplace injuries can also be reported at a national level in accordance with Australian Standard 1885.1. The purpose of this standard reporting system is to make sure that national work accident statistics are uniform and reliable. These statistics are used by the government for purposes such as planning accident prevention strategies and allocating resources.

All workers have a responsibility to provide accurate and truthful information about workplace accidents. Information may have to be given to a supervisor or you may be asked to complete an accident report yourself.

REFLECT & RESPOND

Before leaving this page, think of what you’ve just been reading, and test yourself with this question.

[[ mr /f ][ Which of the following statements regarding Emergency Action Principles are accurate: – ][ Survey the scene to ensure no danger is present. ][ Call emergency personnel if anyone needs paramedical attention. ][ * When you phone 000 the emergency operator will know your location from your telephone number. ][ * A secondary survey is needed to find other accident victims. ][ A primary survey involves assessing the condition of the injured party. ][ 000 operators need location information; secondary survey relates to the already identified, injured party. ]]

[[ sh /n ][ Examples & Extracts ]]

Occupational Health & Safety requirements in the construction industry vary only slightly from state to state. Often the main difference is only in the terms that are used while the OH&S issues are basically the same.

The examples which follow are extracts from typical construction site documents. They are included to help you understand the need for all workers to comply with OH&S requirements on the construction site.

SITE RULES

The following list of site rules is an extract from a typical Principal Contractor’s Construction Workplace Plan or Site Safety Plan. All workers and sub-contractors on the construction site are required to comply with the site rules.

- All incidents, injuries and emergency situations must be reported to the site supervisor and work group supervisor.

- Workers must wear correct personal protective equipment (as per work method statements/JSA’s, MSDS’s or manufacturer’s recommendations) during specified work activities.

- Rubbish must be placed in the appropriate bin/skip provided before leaving the site each day.

- Work areas are to be kept clean and access ways free from hazards at all times.

- No alcohol or illegal drugs are permitted on the construction site.

- Persons who are affected by alcohol or drugs will be denied access to the site.

- The toilets provided are to be used and good hygiene is to be practised at all times.

- Before a hazardous substance can be stored or used on the site, a copy of the relevant MSDS must be lodged with the site supervisor or included in the relevant work method statement/JSA.

- All personnel who use plant and equipment must have received appropriate equipment or safety device that belongs on the construction site. This includes scaffolds, handrails, barricades, signage, guards, etc.

- Electrical equipment including leads must be inspected and tagged at intervals not exceeding six months and maintained in locations where they are not likely to be damaged or create a trip hazard.

- Piggyback leads and double adaptors are not to be used on site.

- Work above three metres will require a means of fall protection.

- Theft of any kind will not be tolerated and will be reported directly to the police.

- All safety signs are to be complied with in full.

- Vehicles or equipment reversing onto or off the site will be guided by a spotter to safeguard workers and other pedestrians in the area.

WORK METHOD STATEMENT / JSA

The following is an extract from a typical Work Method Statement or Job Safety Analysis for roof tilers who are to work on a house roof where they could risk falling three metres or more to the ground.

Task Hazard/Risk

Falling 3m or more while accessing the roof.

Method Of Control

- The Principal Contractor will erect scaffolding around the perimeter and will provide a copy of the scaffold plan, showing the scaffolding contractor’s name and contact details.

- Scaffolding will have a mesh guard around its perimeter.

- Provide ladders for access where necessary. Ladders will be placed on a level base at an angle of 70º to 80º, will extend at least 1m beyond the access point and be secured at the top and/or bottom before being used.

Task Hazard/Risk

Falling 3m or more while laying tiles on the roof.

Method Of Control

- Timber battens including spans will comply with AS1684 – National Timber Framing Code. Refer to Roof Drawing for further details.

- The battens will be strong enough to prevent a fall through the roof.

- Battens will be laid from the tail of the rafter to the ridge.

- Only trained, experienced roofing workers will do the work.

Inspection

- Before work starts each day the on-site foreman will do a brief visual inspection of the scaffolding and roof to ensure that the scaffolding is in accordance with the scaffolding plan and that the roof is generally safe to access.

- When a scaffold risk is identified there will be no access until the matter has been referred to the Principal Contractor or scaffolding sub-contractor and they have taken measures to correct the fault.

On-going Monitoring of Scaffold and Roof

- Workers will constantly monitor their method of scaffold access, and access across roof battens.

- If a serious risk is detected, all workers will be removed from the roof and not be allowed to return until controls have been implemented, for example modify scaffold or repair/add roof battens.

MATERIAL SAFETY DATA SHEET (MSDS)

The following is an extract from a manufacturer’s MSDS for a silicone building sealant used to seal the joints between large pre-cast concrete panels. Tilt-up panels are often used to construct the walls of commercial and industrial buildings. The information included here is a summary of the parts of the MSDS that relate to a worker’s every-day use of the product. Other information on an MSDS includes the manufacturer’s name and contact details as well as technical data about the product, chemical names of ingredients and a list of hazardous components.

Effects Of Over-Exposure

Eye: Direct contact may cause mild irritation.

Skin: May cause moderate irritation.

Inhalation: Vapour may irritate nose and throat and cause drowsiness.

Oral: Low ingestion hazard in normal use.

Prolonged/Repeated Exposure Effects

Skin: No known applicable information. Inhalation: Prolonged over-exposure by inhalation may injure the following organs: liver, kidneys, bone marrow, testes, immune system. Oral: Repeated ingestion or swallowing large amounts may cause internal injuries.

FIRST AID MEASURES

Eye: Immediately flush with water for 15 minutes. Skin: Remove from skin and wash thoroughly with soap and water or waterless cleanser. Get medical attention if irritation or other ill effects develop or persist.

Inhalation: Remove to fresh air. Get medical attention if ill effects persist. Oral: Get medical attention. Comments: Treat according to person’s condition and specifics of exposure.

FIRE FIGHTING MEASURES

Extinguishing:

Large fires – dry chemical, foam or water spray.

Small fires – carbon dioxide (CO2), dry chemical or water spray.

Water can be used to cool fire exposed containers.

Small fires – carbon dioxide (CO2), dry chemical or water spray.

Water can be used to cool fire exposed containers.

Safety:

Self-contained breathing apparatus and protective clothing should be worn when fighting large fires involving chemicals.

Handling And Storage

Use with adequate ventilation or use respiratory protection. Avoid eye and skin contact. Avoid breathing vapour, mist, dust or fumes. Do not take internally. Keep container closed. Store away from heat, moisture or water.

Personal Protection For Routine Handling

Eye: Use proper protection – safety glasses as a minimum.